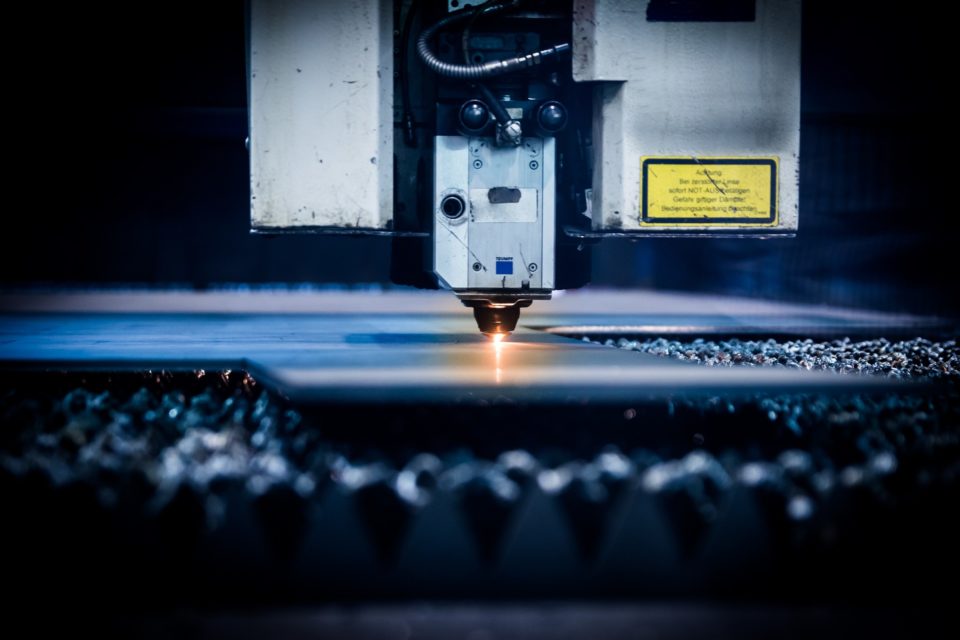

It doesn’t matter if you are the proud new owner of a laser engraver or if you are an accomplished and experienced engineer; using the right way to use this powerful design equipment is a must. By taking the time to learn what to do and avoid, you can keep from making some of the most common mistakes.

There’s a good chance you put time and effort into finding the right laser cutter. This may have included researching brands and looking at customer reviews. Now it is time to learn the dos and don’ts of using this machine. Part of this process is finding out about the most common mistakes that are made. Keep reading to learn what these are.

Burning the Material When Engraving Fabric

To avoid burning fabric while cutting or engraving, it is to understand what types of fabrics can withstand the process and their rated temperatures. Some thicker and heartier fabrics like canvas, leather, and denim will withstand higher temperatures while engraved. However, for more delicate fabrics, the laser cutter or engraver settings should be set at low power (approximate five or 10%) and high speed (almost 100%). Be sure to test the settings on a scrap piece of the material first to ensure it can withstand the settings.

For direct-to-garment engraving, it is a good idea to reduce the DPI – dots per inch – that the engraver is set at. The higher the DPI is, the more material that will be removed. By setting the DPI to a lower setting, the laser will vaporize the very top layer without burning through the fabric. Most people find that engravings on fabric do well when set between 150 and 300 DPI.

The Lack of a Frosty White Look When Engraving on Acrylic

If the desired frosty white look is not achieved when using a laser to engrave on acrylic, it is probably with the application process. Today, two main types of acrylics are used for this. Each is suitable for a unique application.

The first is cast acrylic. This material is created from a liquid acrylic poured into a mold. It can then be shaped into different things. This acrylic is great for engraving because it will turn the desired frosty white colour when engraved. This makes it a great option for plaques and awards.

The other common type of acrylic that is used is extruded acrylic. A machine forms this material into sheets. While this acrylic type is usually more affordable than cast acrylic, it will react differently to a laser engraver. For example, it does not create that frosty white appearance that so many people want.

Getting Laser Engraving and Cutting Right

There are a few factors to consider when it comes to using a laser engraving or cutting machine. Keep the tips and information here in mind to feel confident that the desired results are achieved and that no other issues will arise. By doing this, a person can make the most out of their laser cutter and engraver and get the best quality results possible.